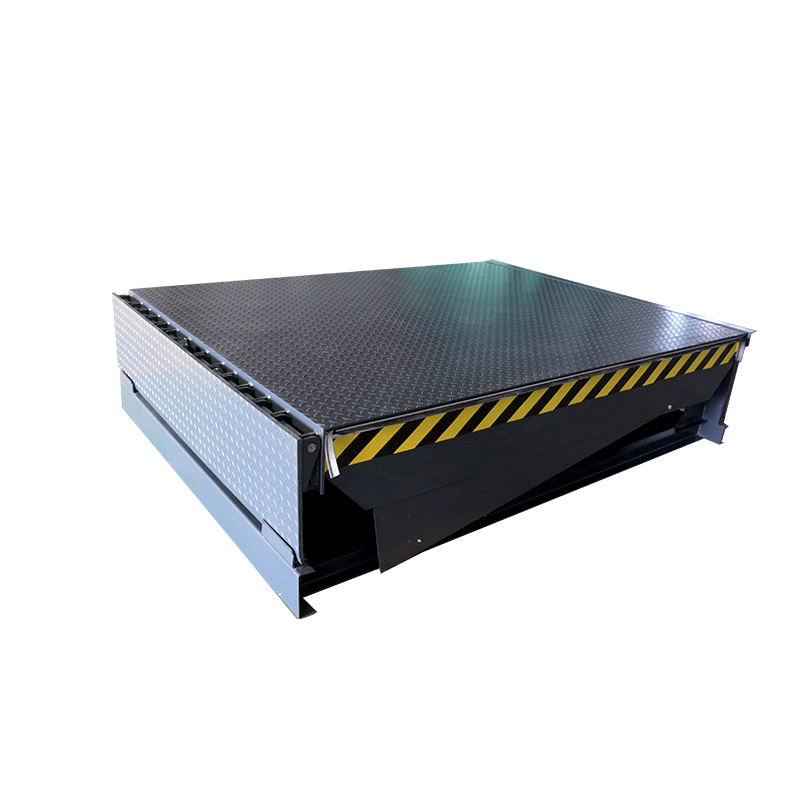

The embedded loading ramp is widely used because of its large adjustment range. Unless the height difference between the bottom of the truck and the cargo platform is very small,

do not easily design or choose a platform-type boarding bridge. The service life of thedock ramp is very long, and it has a great influence on the operation efficiency of the whole system,

so when choosing thedock ramp, it is extremely important to accurately determine the following elements of the loading ramp:

● Length

● width

● Lap length

● Load capacity

● Power system

● Adaptation to the environment

1. loading ramp length

The length of the boarding bridge directly affects the slope of the inclined plate during use.

This slope is smaller than the maximum slope that the loading and unloading tool can bear.

The required length of the boarding bridge is determined by the maximum height difference

between the platform and the truck floor Decide.

In order to drive flexibly and safely on the boarding bridge, the loading and unloading equipment must

have sufficient ground clearance (Ground Clearance)

When using a pallet truck on a platform-type boarding bridge, it is particularly important that the truck has sufficient ground clearance,

otherwise there will be friction between the bottom of the loading

and unloading equipment and the surface of the boarding bridge. When using pallet trucks on built-in bridges,

the ground clearance is usually sufficient

2.dock ramp Width

The boarding bridge has three widths of 1.8, 2.0 and 2.1 meters, the most commonly used is 2.0 meters,

which is suitable for loading and unloading of most palletized cargo transport vehicles.

3.Lap length

The loose-leaf board at the front end of the boarding bridge must extend enough length into the truck to ensure a firm and reliable support.

According to the American National Standards Institute MH4.

1 standard, this length should not be shorter than 10 cm. In most cases, the standard board can protrude 30 cm outside the

anti-collision rubber, which can provide sufficient support.

For special compartments, consider using a longer board. The bottom plate of the refrigerated truck has a special structure,

and a board of 35 cm or longer is required.

4.Load capacity

If the load-bearing capacity of the boarding bridge is properly selected, the service life of the boarding bridge can be greatly increased.

The choice of the loading capacity of the boarding bridge depends

largely on the gross gross weight (GVW) of the forklift using the boarding bridge. It includes the weight of the forklift and the

weight of the fully loaded cargo (with the operator).

Electric forklifts should include the weight of the battery. Generally, for propane and gasoline-powered forklifts, the empty weight is 170-210% of its bearing capacity.

Because of the battery, the electric forklift weighs

500 to 800 kilograms more. (For example, a forklift with a load of 1 ton has a self-weight of at least 1.7 tons).

In order to determine the bearing capacity of the boarding bridge,

the gross gross weight (GVW) of the forklift should be determined first. The minimum bearing capacity of the boarding bridge is the

total gross weight of the forklift multiplied

by the safety factor of 1.5. If one of the following situations occurs, multiply by 2. 1. If two or more situations occur, multiply by 2.55.

Factors affecting load bearing:

● More than 8 trucks use the same boarding bridge every day

● Forklifts will shift direction on boarding bridges instead of going in a straight line

● Use a three-wheel forklift

● The speed of the forklift on the boarding bridge will be higher than 6 km/h

● Special devices are installed on the front or both sides of the forklift (such as barrel clamping machine, etc.)

5.power system

From the perspective of operational efficiency and safety, the electric button type is the general trend of the power system of the boarding bridge;

the manual spring mechanical type is only used when the

power supply cannot be supplied near the loading and unloading platform or the factory building has explosion-proof requirements.

The electric button type has the characteristics of less maintenance and less adjustment, and the cost is the lowest in the long run.

6.Environmental adaptability

For wall-penetrating platforms that meet the needs of environment and humidity control, it is necessary to consider adding

auxiliary weather seals to the boarding bridge to reduce air infiltration through the edge gap of the boarding bridge pit.

The back of the boarding bridge installed in the cold storage needs to be heat-insulated; otherwise, the condensation of water

vapor will corrode the back of the boarding bridge, causing premature damage to the mechanical structure. The heat insulation

treatment layer can prevent hot air from contacting the back of the boarding bridge,

so that Water vapor will not condense on the metal surface; at the same time, the thermal insulation treatment layer also reduces the loss of cold air inside the building.

Leave a comment

your email address will not be published. required fields are marked *

You may also like

86 19963481610

Building 24, Jigao Intelligent Park, Jinan City, Shandong Province

Copyright © Wemet Lift Machinery Co., Ltd. All Rights Reserved | Sitemap Technical Support: